WooCommerce Inventory Management: Get Yours Organized Now

“Sold out” – two words that are almost guaranteed to lead to disappointed customers.

The thing is, when those words refer to a product that should be in stock in your WooCommerce store, it’s also costing you money. You can’t always help when products sell out before you can restock, but it’s a good reason to get your inventory management ship-shape.

In fact, efficient inventory management is a core characteristic of successful retailers. If you haven’t got a robust system in place, now is the time to get it organized:

Why WooCommerce inventory management is important

Inventory management refers to the set of activities required to ensure that you have enough inventory when you need it without buying too much. This sounds simple enough, but in reality, there are a number of issues that impact inventory.

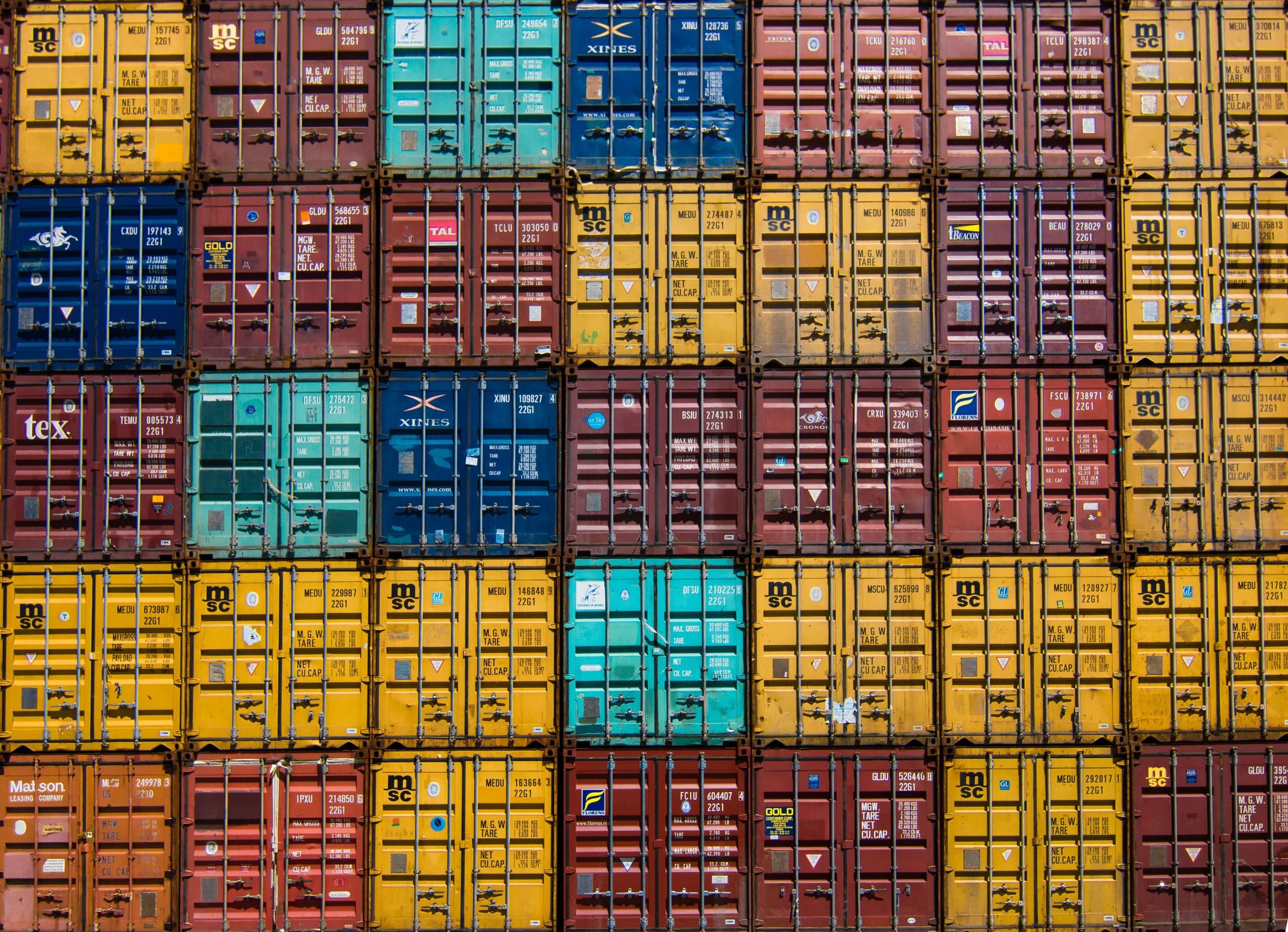

Right now, cargo ships are lined up for miles, held outside of ports while they wait for a space to offload. If you happen to be one of the thousands of retailers with incoming products on those ships, you might already be in a bind over replenishing your inventory in a timely manner.

More commonly though, when retailers lose track of inventory management, issues such as stock-outs can take them by surprise. If you usually sell 100 units per week of your most popular item, you have 200 units left, but getting new stock has a four week turnaround, you’re set to run out of stock in two weeks and remain that way for at least two weeks.

Meanwhile, one of the biggest problems with stock-outs is that there’s a high chance you’re losing a lot of sales. Customers who came to your site to buy might just look elsewhere, or, they might forget to try you again because they couldn’t make a purchase the first time.

The opposite problem is having too many products sitting on the shelf. You’re probably paying to warehouse your products and it makes no sense to pay for products that aren’t selling quickly enough. Some may be dated (such as perishable goods), which means you run the risk of having to write them off completely.

Good inventory management helps you to have a clear picture of your best and worst-performing products. It helps you to plan ahead so that you don’t lose money due to stock-outs, or have money sitting on the shelf due to too much inventory. Furthermore, it’s about maintaining good customer relationships. If the customer goes elsewhere, you don’t even get to try to build an ongoing relationship with them.

Good inventory management helps you to optimize inventory and boost revenue Share on XKey challenges with inventory management

One of the big challenges of inventory management is that many retailers still use some form of manual tracking. They might use a combination of different software and spreadsheets, which means nothing is centralized. That can mean inaccuracies creep in, especially if a spreadsheet that relies upon manual entries isn’t updated. Time is often a challenge: you have to carve out space in your busy day to make manual updates, or to notice when something needs actioning, and it can easily become something you put off.

Another challenge (which often comes from manual processes) is inaccurate data. Your spreadsheet shows that you should have 200 units left, but in reality, you have 120. If you like to operate a “just in time” ordering system, you’ll probably miss the correct reorder date because you think you have more stock than you really do.

Supply chain complexity can be another inventory management issue. If you don’t make the product yourself right where you are, then it needs to get to you (or your fulfillment warehouse) from somewhere. Products have a lead time for manufacturing and shipping. Sometimes supply chain issues impact those lead times, such as when raw materials are held up. You can’t plan for every circumstance, but you can build in sufficient lead times to create a buffer.

Tips for better WooCommerce inventory management

The point of all of this is that improving your inventory management can help to improve your bottom line. Avoid losing sales due to stock-outs, or having stale inventory languishing on the shelf. Here are some tips for improving WooCommerce inventory management:

- Use reliable, automated inventory management software. A good inventory management software is a “single source of truth” for all things inventory. This means that stock numbers should always be updated and that you get alerted when inventory reaches your pre-determined reorder levels. You shouldn’t have to manually check to find out whether you should be ordering more stock – an automated system will tell you.

- Choose your suppliers carefully. Sometimes suppliers are at the root of supply chain issues. It’s important to do your due diligence before selecting them, and weigh up relative pros and cons. Look at things like their experience and relevant certifications, their customer reviews, and the turnaround time required for orders. Pay attention to their warranties or guarantees too – what happens if you’re sent a faulty batch of something?

- Look for trends and patterns. You might have an automated inventory management system, but you still need to be in the loop. Look at the inventory reports for any trends, such as products that are becoming more or less popular. Consider how surges in sales (such as over the holiday season) will impact your inventory. Another good source of data is your customers – stay on top of any feedback (especially involving product quality).

- Conduct frequent stock audits. If returns and exchanges aren’t properly entered into the system, or if stock gets taken from where it is stored, this won’t be reflected in your inventory management system. It’s important to keep up regular counts.

- Maintain safety stock. This is an amount of stock kept as a buffer to try to prevent stock-outs. If there are any supply chain disruptions or extensions of lead times, the hope is your safety stock will see you through.

- Classify inventory. Create categories by size, packaging type, weight and product. This will help you to control your shipping costs and storage needs.

Plan ahead for the holiday season! This is the time of year when many retailers make more money than the entire rest of the year combined. You can expect to need extra inventory, and getting replenishments may need a longer lead time. Some manufacturers shut down altogether for a period around the holidays, so it’s important to check in and find out what yours are doing.

Plan ahead for the holiday season! This is the time of year when many retailers make more money than the entire rest of the year combined. You can expect to need extra inventory, and getting replenishments may need a longer lead time. Some manufacturers shut down altogether for a period around the holidays, so it’s important to check in and find out what yours are doing.

Final thoughts

Implementing good inventory management practices can make a huge difference for your overall bottom line. It means optimizing your inventory so that it’s always available to those who want to buy, while avoiding having too much stock languishing on the shelf.

One of the most important steps you can take is to find a good automated inventory management system that is compatible with your WooCommerce store. Your system should alert you to when reorders are needed and should keep an accurate record of all inventory. It should also provide you with useful reporting features.